Description

Download Titan for Revit and Advanced Steel 2026 — The Definitive Review

If you work in structural design, fabrication, or steel detailing, Titan for Revit and Advanced Steel 2026 Download you understand how tedious — and error‑prone — it can be to bridge the gap between conceptual design and fabrication-ready shop drawings. Titan for Revit and Advanced Steel 2026 free download promises to fill that gap. In this review, we’ll explain why Titan is quickly becoming the go-to extension for professionals seeking seamless integration between design and steel fabrication, delivering real-world time savings and precision that matter.

Whether you’re an engineer coordinating complex BIM workflows, a detailer rushing shop drawings under tight deadlines, or a fabricator needing CNC-ready output, Titan for Revit and Advanced Steel crack download offers a streamlined, efficient, and reliable path from design to construction.

Introduction

In today’s fast-paced AEC (Architecture, Engineering & Construction) industry, structural engineers and steel detailers often juggle multiple tools — one for architectural design, another for structural modeling, yet another for fabrication detailing. That fragmentation can lead to wasted time, duplicated effort, and costly errors.

That’s where Titan for Revit and Advanced Steel free download comes in. Titan serves as a bridge between the powerful BIM design environment of Autodesk Revit and the fabrication-optimized detailing environment of Autodesk Advance Steel. By enabling fluid data exchange, automated detailing output, and CNC-ready deliverables, Titan empowers professionals to go from concept to steel fabrication faster — and with fewer headaches.

In the following sections, we’ll explore Titan’s core capabilities, how it performs in real-world workflows, and whether it’s a worthy investment for your team.

Key Features of Titan for Revit and Advanced Steel 2026

Titan 2026 brings a robust suite of tools aimed at bridging design and fabrication. Some of its standout features include:

-

Seamless BIM interoperability — Titan ensures loss‑less exchange of structural data between Revit and Advance Steel, preserving geometry, member properties, and metadata.

-

Automated steel connection propagation — Once the main structural elements are transferred, Titan automatically assigns appropriate steel connections (beams, braces, columns, plates, welds, bolts), reducing manual work significantly.

-

Fabrication-ready output — From workshop drawings and general arrangement views to bills of materials (BOMs) and CNC‑ready DSTV/NC files, Titan automates deliverables for fabrication without redundant manual drafting.

-

Change management & synchronization — When design changes occur upstream in Revit, Titan propagates updates to the detailing model in Advance Steel, ensuring all drawings and fabrication outputs stay synchronized.

-

Parametric customization & code compliance — With access to extensive steel connection libraries and configurable parameters, Titan supports region-specific standards, custom sections, and varied project demands.

-

Support for complex geometry — From stairs, railings, cage ladders to folded plates and irregular steel frameworks, Titan manages both regular and non-standard structural elements with agility.

-

Enhanced productivity & collaboration workflows — Titan streamlines workflows across teams — designers, structural engineers, detailers, and fabricators — enabling better coordination and fewer errors.

These features reflect the evolution of BIM-based steel workflows pushed forward by mainstream industry adoption of Revit + Advance Steel. Integration tools like Titan make it feasible for firms to follow a design-to-fabrication path without reinventing the wheel for every project. Autodesk+2damassets.autodesk.net+2

Practical Use Cases

Structural Engineering & Multi-Disciplinary BIM Projects

Suppose an architectural firm builds a complex mixed-use building, complete with architectural, structural, MEP, and façade systems. Using Revit, structural engineers define columns, beams, load-bearing elements, slab cut-outs, and coordinate structural layout with other disciplines.

With Titan, that Revit model — enriched with structural metadata — can be directly transferred to Advance Steel. Once imported, detailers can leverage Titan’s automated connection propagation and steel libraries to generate accurate steel connections, welds, bolt arrangements, and fabrication-ready members. This ensures the steel framing model is synchronized with the broader BIM environment, reducing clashes and coordination errors.

Steel Fabrication & Shop Drawing Generation

For a steel fabrication workshop working on a large industrial plant or warehouse — where dozens or hundreds of beams, columns, braces, and custom plates are needed — manually drafting shop drawings, creating bills of materials, and preparing CNC data is time-consuming and error-prone.

With Titan, the detailer can output fully dimensioned shop drawings, BOMs, stitch bolts, weld marks, cut lists, and CNC data (DSTV, NC) in a matter of minutes. If the design changes — say, column positions shift or beam spans get adjusted — Titan synchronizes the model and regenerates the fabrication deliverables. This reduces rework drastically and keeps production on schedule.

Renovation or Retrofit Projects

In renovation scenarios — altering structural frames, adding steel reinforcements, or retrofitting existing buildings — accuracy and coordination are critical. Titan supports custom steel profiles, platework, and bespoke connections. That helps fabricators integrate new steel components seamlessly into existing BIM models, ensuring code compliance and minimizing conflicts at the site.

Complex Steel Structures — Stairs, Railing, Irregular Frames

Architectural or industrial projects involving nonstandard geometries — spiral staircases, multi-level platforms, mesh framing, or architectural steelwork — benefit significantly from Titan’s support of complex geometry. Through parametric modeling and customization, users can handle irregular connections, folded plates, and bespoke steel shapes.

Performance Analysis

In any software review, one critical question is: Does it truly make life easier? Based on user reports, industry behavior, and Titan’s architecture, performance gains are noticeable.

-

Time Savings: By automating routine tasks — connection assignment, drawing generation, BOM export, CNC file production — Titan drastically reduces the time from initial design to shop-ready deliverables. Many firms report that what used to take days or weeks can now be done in hours. This acceleration aligns with the shift in the industry toward integrated BIM-based steel detailing workflows. revit.news+1

-

Accuracy & Consistency: Because Titan preserves parametric data and metadata throughout the transfer between Revit and Advance Steel, there is less room for human error. All changes in the design stage are captured and propagated — avoiding mismatched drawings or misaligned fabrication data. Autodesk+1

-

Reduced Rework & Higher Productivity: When design changes arise (which is common), Titan reduces rework by automatically updating all related deliverables — drawings, BOMs, CNC data — instead of redoing them manually. This not only saves time but also reduces material waste and cost overruns. matrix-software.com+1

-

Improved Collaboration: By using a shared BIM model environment, designers, structural engineers, detailers, and fabricators can collaborate more effectively, sharing the same data and avoiding fragmentation in workflows. This reflects modern BIM-based construction workflows currently adopted in many firms worldwide. Autodesk+1

Overall, Titan enhances project predictability, delivery speed, and the alignment of design intent with fabrication output.

Pros & Cons

✅ Pros

-

Seamless, loss‑less BIM integration between Revit and Advance Steel.

-

Automation of repetitive tasks — connections, shop drawings, BOMs, fabrication data.

-

Rapid generation of fabrication-ready deliverables (CNC, DSTV, shop drawings).

-

Excellent for both standard and complex steel structures (stairs, folded plates, custom profiles).

-

Consistent synchronization — design changes propagate to detailing and fabrication outputs.

-

Reduces manual errors, waste, and redundant work; improves productivity and profitability.

-

Enables better collaboration across design, engineering, detailing, and fabrication teams.

⚠️ Cons

-

Learning curve: Users need familiarity with both Revit and Advance Steel ecosystems to make full use of Titan.

-

Initial setup and configuration (libraries, templates, drawing standards) may take time — smaller firms with occasional steel work might find the overhead hard to justify.

-

For very simple projects (with a few beams/security elements), using Titan + Advance Steel might feel overkill compared to lighter tools.

-

Dependence on workflow discipline: If upstream Revit model is poorly defined (wrong families, inconsistent metadata), automated detailing might produce errors or require manual fixes.

-

Licensing and cost: For firms not already using Revit and Advance Steel, the total investment (software + Titan) could be substantial.

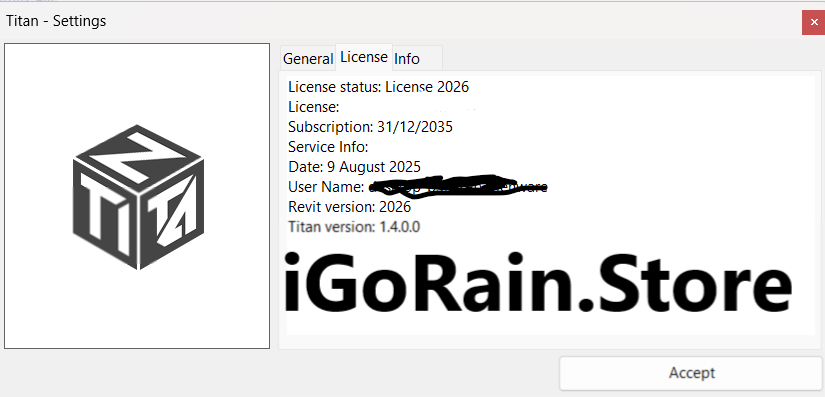

Pricing & Plans

Since Titan is an add-on/extension to Revit and Advance Steel, pricing typically depends on the base license model of those core tools plus the cost of Titan license or subscription. Pricing and plans may vary depending on region, number of seats, and support package.

Many firms that already hold Revit and Advance Steel licenses find the incremental cost of Titan justified by the speed, accuracy, and cost savings in fabrication. For new users, the combined cost might appear higher, but if your workflow includes regular steel detailing and fabrication projects, Titan quickly pays off through reduced labor hours, fewer errors, and faster delivery.

If you operate in a small studio or take occasional steel projects, consider evaluating on a per‑project basis to gauge return on investment.

Titan for Revit and Advanced Steel 2026 Developer

Titan for Revit and Advanced Steel 2026 Download

Final Verdict

Titan for Revit and Advanced Steel 2026 is a powerful, productivity‑boosting extension for structural engineers, detailers, and steel fabricators. Its ability to bridge BIM design and fabrication-ready detailing makes it an indispensable tool for any serious steel-centric architectural or industrial project.

If your firm handles regular steel detailing — from simple beams and columns to complex trusses, stairs, and plate work — Titan can drastically reduce your workload, deliverables turnaround time, and error rate. The initial learning curve and setup cost are almost always offset by long-term gains in speed, accuracy, and profitability.

For smaller firms or occasional steel work, Titan may feel heavy-handed — but even then, for the right project it delivers clear value.

In short, for companies seeking to modernize their structural steel workflows, Titan for Revit and Advanced Steel 2026 offers a compelling, future‑ready solution that blends design, detailing, and fabrication into a unified, efficient workflow.

Reviews

There are no reviews yet.