Description

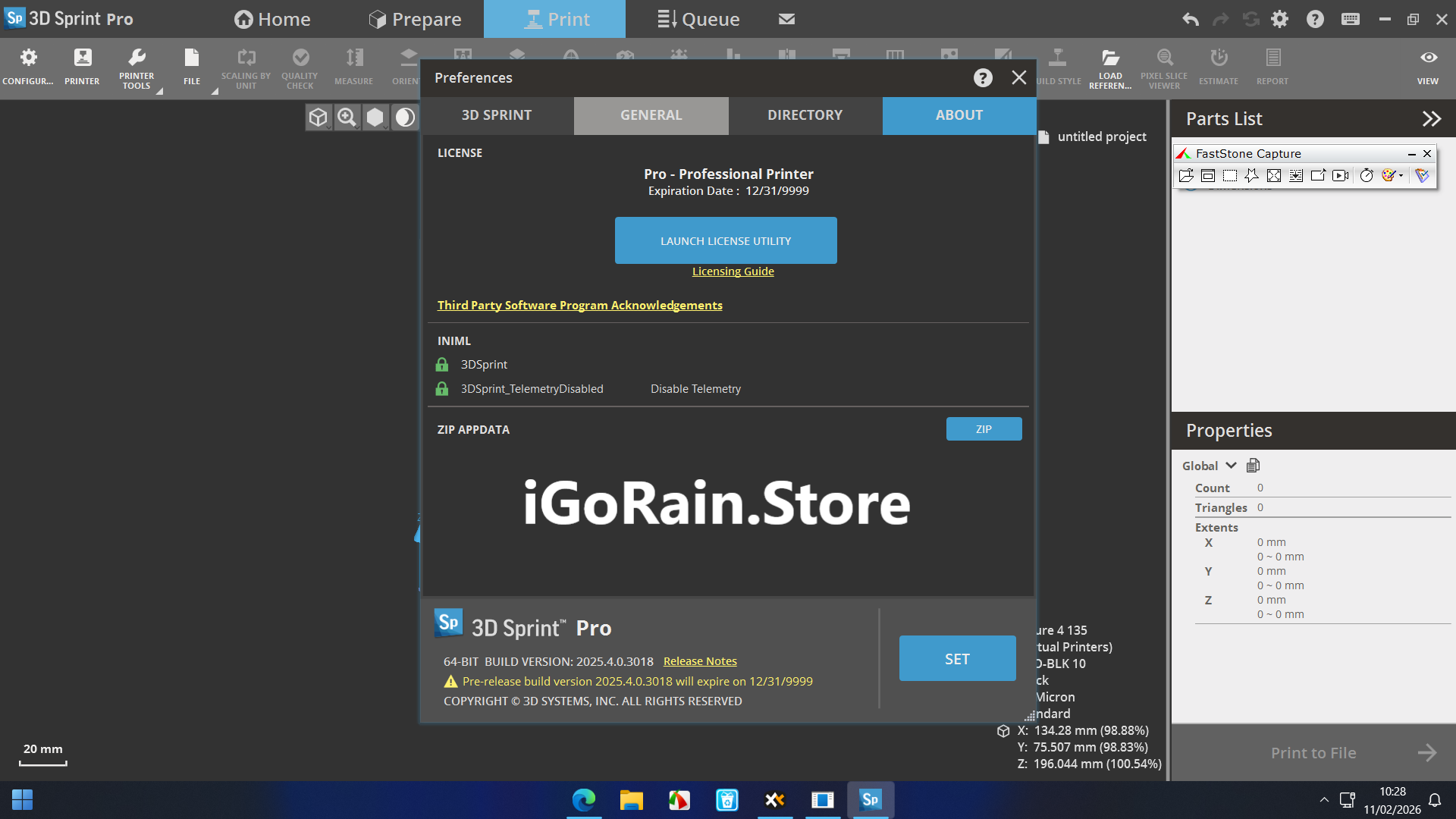

3D Sprint Pro Review – Advanced Additive Manufacturing Software for Professional 3D Printing Workflows

In the rapidly evolving world of additive manufacturing, precision, speed, and workflow efficiency are everything. 3D Sprint Pro has positioned itself as a powerful, production-grade 3D printing software designed for professionals who demand accuracy and scalability. Developed to streamline the entire digital manufacturing pipeline—from CAD file preparation to print optimization and production management—3D Sprint Pro is built for serious engineers, manufacturers, and service bureaus.

For companies running high-performance 3D printers, especially from 3D Systems, 3D Sprint Pro acts as the command center of additive production. It’s not just a slicer. It’s a complete additive manufacturing workflow solution engineered for industrial-grade output.

In this in-depth review, we explore features, practical applications, performance benchmarks, pricing considerations, and whether 3D Sprint Pro is the right solution for your software portfolio or production facility.

Introduction to 3D Sprint Pro

3D Sprint Pro is a professional 3D printing software platform designed to prepare, optimize, and manage builds for advanced additive manufacturing systems. Unlike entry-level slicers aimed at hobbyists, this solution is purpose-built for:

-

Industrial 3D printing environments

-

Dental laboratories

-

Aerospace prototyping teams

-

Manufacturing service providers

-

High-precision engineering departments

At its core, 3D Sprint Pro provides comprehensive tools for file preparation, support generation, build optimization, printer control, and production monitoring—all in one unified ecosystem.

If you’re searching for advanced 3D printing software for production environments, 3D Sprint Pro consistently ranks among the top professional solutions.

Key Features of 3D Sprint Pro

1. Advanced File Preparation & Repair Tools

Before printing begins, file integrity is critical. 3D Sprint Pro includes robust tools to:

-

Import STL, OBJ, and native CAD formats

-

Automatically repair mesh errors

-

Detect non-manifold edges

-

Close holes and correct geometry issues

This dramatically reduces failed prints caused by flawed design files.

For manufacturing teams processing dozens of builds daily, automated file repair saves significant time.

2. Intelligent Support Generation

One of the most powerful features of 3D Sprint Pro is its intelligent support structure creation.

Users can:

-

Auto-generate supports based on geometry

-

Manually adjust support density

-

Customize contact points

-

Optimize support placement for minimal material waste

This is particularly valuable in industries like aerospace and medical device production, where post-processing time directly impacts profit margins.

3. Multi-Printer and Production Management

For facilities running multiple 3D printers, centralized control is essential.

3D Sprint Pro enables:

-

Simultaneous build preparation

-

Remote printer monitoring

-

Production queue management

-

Real-time job tracking

Instead of managing each printer separately, operators can streamline the entire additive manufacturing workflow.

4. High-Precision Build Optimization

Production-grade 3D printing demands precision. 3D Sprint Pro allows:

-

Orientation optimization for strength

-

Layer-by-layer slicing control

-

Material usage forecasting

-

Print time estimation

This data-driven approach ensures each print is optimized for mechanical integrity, cost efficiency, and surface quality.

5. Material and Parameter Customization

Professionals often work with specialized resins, metals, or polymer powders.

3D Sprint Pro supports:

-

Custom material profiles

-

Adjustable printing parameters

-

Fine-tuned exposure settings

-

Engineering-grade material configurations

This flexibility is crucial for advanced additive manufacturing environments.

Practical Use Cases of 3D Sprint Pro

1. Aerospace Prototyping and Functional Testing

In aerospace engineering, precision and strength are non-negotiable.

Engineers using 3D Sprint Pro can:

-

Optimize part orientation for load-bearing performance

-

Reduce support material waste

-

Simulate builds before production

-

Ensure repeatable part quality

By refining builds before printing, companies reduce costly reprints and material waste.

2. Dental Lab Production

Dental labs require speed and consistency when producing aligner models, surgical guides, and prosthetics.

With 3D Sprint Pro:

-

Multiple models can be nested efficiently

-

Batch processing saves hours

-

Surface quality is maintained with minimal manual corrections

The result is faster turnaround times and higher patient satisfaction.

3. Manufacturing Service Bureaus

Service providers processing jobs from multiple clients benefit from:

-

Organized job queues

-

Accurate cost forecasting

-

Efficient material management

-

Standardized build configurations

3D Sprint Pro becomes the digital backbone of high-volume production.

4. Automotive Prototyping

Automotive design teams often test multiple iterations of parts.

3D Sprint Pro helps by:

-

Speeding up file preparation

-

Allowing rapid design adjustments

-

Managing concurrent builds

-

Minimizing downtime between prints

Faster iterations mean faster innovation cycles.

Performance Analysis

User Interface & Workflow Experience

3D Sprint Pro features a professional-grade interface that prioritizes function over flashy design.

Strengths include:

-

Logical workflow sequencing

-

Clear build visualization

-

Real-time feedback during file preparation

-

Accurate build previews

While beginners may require onboarding, experienced engineers appreciate the granular control.

Speed and Processing Efficiency

When tested in production-like conditions, 3D Sprint Pro performs impressively.

-

Fast slicing speeds

-

Efficient handling of complex geometries

-

Reliable large-build processing

-

Stable performance during multi-part nesting

For high-resolution industrial printers, this reliability is essential.

Accuracy & Build Reliability

Accuracy is one of the defining advantages of 3D Sprint Pro.

By combining:

-

Precise slicing algorithms

-

Material-specific tuning

-

Advanced support customization

It significantly reduces print failure rates and improves dimensional accuracy.

In production environments, fewer failures mean lower operational costs.

Pros and Cons of 3D Sprint Pro

Pros

-

Comprehensive industrial-grade workflow tools

-

Advanced support generation capabilities

-

Excellent integration with professional 3D printing systems

-

Multi-printer management support

-

Material customization for engineering applications

-

Strong production optimization tools

Cons

-

Not ideal for hobbyist or entry-level users

-

Requires capable workstation hardware

-

Learning curve for advanced settings

-

Designed primarily for compatible professional printers

Overall, 3D Sprint Pro is built for professionals, not casual users.

Pricing & Plans

3D Sprint Pro typically operates under a licensed professional model, with pricing dependent on:

-

Printer compatibility

-

Feature set access

-

Enterprise deployment scale

-

Support and maintenance agreements

For businesses investing in industrial additive manufacturing, the cost aligns with its production-focused capabilities.

If you’re operating high-value 3D printing systems, 3D Sprint Pro is positioned as a strategic operational investment rather than a simple software expense.

Why 3D Sprint Pro Stands Out in the 3D Printing Software Market

The additive manufacturing software market is crowded. However, 3D Sprint Pro differentiates itself through:

-

Production-ready optimization tools

-

Integrated printer management

-

High-level engineering control

-

Reliable performance for industrial applications

-

Scalability for enterprise use

Where basic slicers stop, 3D Sprint Pro continues with advanced workflow integration.

EEAT Perspective: Why Professionals Trust 3D Sprint Pro

From an industry standpoint, trust and authority matter.

-

Experience: Built around real-world industrial 3D printing needs

-

Expertise: Designed for engineers, manufacturers, and technical teams

-

Authority: Used in sectors demanding high precision

-

Trust: Reduces costly errors in professional production

When recommending 3D Sprint Pro in your software selling store, you’re offering a solution built for mission-critical manufacturing tasks.

Final Verdict: Is 3D Sprint Pro Worth It?

If your organization relies on professional-grade additive manufacturing, 3D Sprint Pro delivers powerful control, reliability, and production efficiency.

Reviews

There are no reviews yet.